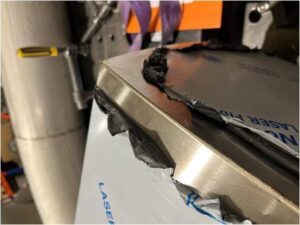

Sheet Metal Processing

Rolling Sheet Metal Parts and Containers

With our horizontal roller (working width: 1,250 mm), we produce sheet metal parts with defined radii as well as fully rounded components – such as small containers or custom pipe sections.

We process materials with wall thicknesses of up to 5 mm – accurately, efficiently, and strictly according to customer specifications.

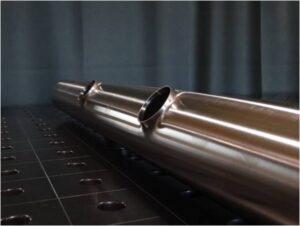

Precise Cutting of Pipes and Profiles

We rely on state-of-the-art technology to cut pipes and profiles – quickly, accurately, and with minimal distortion.

Orbital Saws for Round Pipes

Using two orbital saws in various sizes, we cut round pipes from 12 mm to 330 mm in diameter – with maximum precision and cutting speed.

Perpendicularity and dimensional accuracy of the cut surfaces form the basis for precise, low-stress constructions in accordance with technical drawings.

The cut pipes are welded on our turning devices using TIG and MAG processes – ensuring flawless results, both visually and technically.

Band Saws for Profiles and Beams

We also operate two high-performance band saws, enabling us to cut:

Tubes and profiles up to 460 mm in diameter

Miter cuts up to 60°

Square tubes, rectangular tubes, beams, and special profiles

This guarantees maximum precision for all downstream processing – clean, efficient, and cost-effective.

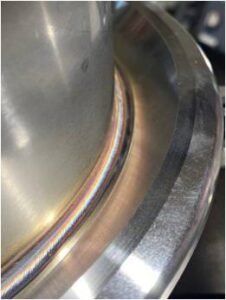

Professional Welding & Fixture Technology

The cut tubes and profiles are processed on modern turning jigs using TIG and MAG welding processes, as well as laser welding—ensuring both technical and visual perfection.

For complex assemblies such as racks, frames, and structures, we offer:

- A variety of clamping tables in different sizes

- A comprehensive range of clamping and fixture technologies

This enables us to tack and weld components with minimal distortion, achieving the highest dimensional accuracy and consistently reproducible quality.

Surface Treatment

Glass Bead Blasting – Uniform & Satin Finish

In our glass bead blasting facility, we process small to medium-sized components made of chrome-nickel steel and non-ferrous metals.

Blasting with iron-free, chemically neutral glass beads creates a uniform, clean, and satin finish—ideal for components used in plant, container, and apparatus construction.

![]() Gentle on materials

Gentle on materials

![]() Visually appealing

Visually appealing

![]() Uniform finish

Uniform finish

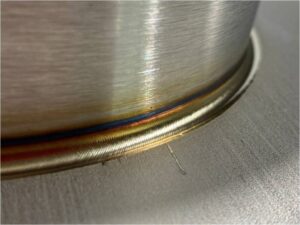

Electrolytic Pickling – For Permanent Corrosion Protection

We pickle weld seams with pinpoint accuracy using carbon fiber brushes to remove oxides and restore the corrosion resistance of stainless steel after welding.

This process is efficient, clean, and particularly suitable for hygiene-critical applications (e.g., in the food or pharmaceutical industries).

![]() Targeted seam treatment

Targeted seam treatment

![]() Restoration of the passive layer

Restoration of the passive layer

![]() Visually clean weld zones

Visually clean weld zones

Pipeline and Frame Construction

With a variety of clamping tables of different sizes and a wide range of accessories, we can tack and weld frames and structures with minimal distortion of the components.

Thanks to the various clamping options, we guarantee high quality and dimensional accuracy.